Rig Modernization Upgrades

Operators began the shift to requiring AC rigs in the mid-2000s. They are faster, safer, and more accurate than DC rigs. Simply put, without AC rigs that meet current modern operator requirements, you lose business. HENDERSON combines technical expertise with innovative solutions that help you drill more wells and win more deals.

Engineering

HENDERSON’s diverse team of talented field engineers and surveyors will quickly tackle your problems. The company specializes in coded ASME vessels, two phase separators, and well control equipment. Working alongside your team, CAD designers will create a complete mechanical design package that meets your needs. You get 24-hour support and scheduling from initial concept to final inspection.

Rig Health Assessment and Market Analysis

When masts and substructures have to be remanufactured and recertified every 10 years, keeping your fleet up-to-date isn’t a “nice to have”, it’s a necessity. HENDERSON is certified to perform full Category IV inspections and complete rig upgrades. Stripping equipment down to bare metal, seasoned technicians inspect each piece of equipment for load stress, cracks, and other flaws. Everything is meticulously restored to manufacture specs so you can operate safely and efficiently. HENDERSON also performs on-site rig health assessments, along with market analysis research and basic rig auditing services.

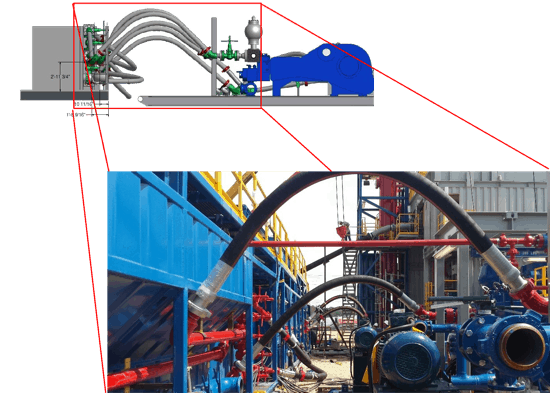

3D Modeling

Working with Autodesk and Solidworks, HENDERSON designers quickly produce 3D assets that accurately represents your project or modification. Get state-of-the-art 3D models that translate your specs into a clear and direct vision.

Brokerage and Sourcing

“Win-win” isn’t just platitude, it’s a way of life. Working through the company’s extensive network of global suppliers, HENDERSON brokers deals that make sense on both sides of the table. Enjoy a smooth transaction from start to finish.