Pipe Fabrication

HENDERSON’s three fabrication shops have the square-footage and strong. The largest of these locations is the Pearland shop which features 82,000 square foot of space and five 10-ton overhead cranes.

Each location maintains a 24/7 production schedule and individually perform roughly 15,000 welds per week and about five vessel fabrications in a typical month.

To ensure that you are getting the highest-quality work possible, HENDERSON holds numerous API, ASME, and ISO certifications. Additionally, all weld procedures are ABS approved.

High Pressure Flowlines

HENDERSON knows that the most crucial part of any drilling operation is also the one that starts right at the well. Of course, we are talking about the well flowlines.

Whether you are moving gas to a tank, compressor station, or a booster station, this pipeline must be properly maintained and inspected for leakage on a routine basis.

HENDERSON stocks single wall flowlines rated for land or subsea wells, in addition to pipe in pipe (PIP) systems to help secure and further protect flowlines that must be installed in operations where it may experience high heat or heavy pipe fatigue.

S-Pipes/Top Drive Goosenecks

HENDERSON supplies a wide variety of S-Pipes/Traps to help you keep your hydrocarbons in check while not needing to alter the pressure of your flow in order to prevent dangerous gasses from seeping through vents or other drainage systems.

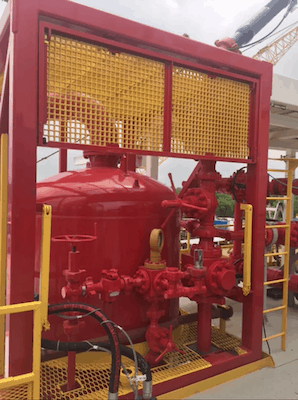

Standpipe Manifold

HENDERSON carries a variety of standpipe manifolds rated for pressures up to 7,500 psi. As with all of our other manifolds, HENDERSON standpipe manifolds are fully certified and meet all current API 16 C and API 16 D standards.

And if we don’t have the standpipe manifold you need in our inventory, we have an in-house team of highly talented engineers and designers who can sit down with you and draft up a design to meet your specifications.

Relief Loops

Relieving pressure in your system is critical for protecting your pressure vessels from building up volatile pressurization which can result in equipment failure, combustion, and loss of revenue due to process interruptions while trying to relieve pressure in the lines or vessels.

HENDERSON offers a wide range of relief loops and pressure relief valves (PRVs) to ensure your liquids and gasses are properly diverted and that your blowdown procedures go off without a hitch.